Dyeing for a Pattern Featuring Asperitas + Rib Lace Raglan

Bonus Content: Process for dyeing the tencel or the wool content

Featuring: 50% Recycled Wool, 50% Tencel

Our Goal: Dye a solid-shade yarn for a specific pattern, and learn how to dye the tencel content or the wool content.

Abstract: Today I’ll show you how to prep and dye a mixed-fiber yarn for both the cellulose content (in this case, tencel) or the protein content (in this case, wool). We’ll learn how to pH test our dye bath to be in the optimal range to absorb the dye and how to get level, even results so the beauty of the pattern takes center stage and the yarn is the supporting act.

YOU WILL NEED:

- 6 skeins of Asperitas from Knomad

- Gloves

- Respirator

- A way to heat set your yarn (steamer, proofer, oven, induction plate)

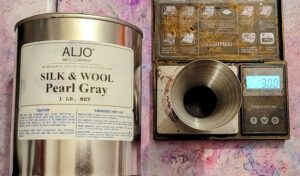

- Acid-Reactive Dye from Aljo in Pearl Grey and Fiber Reactive Dye from Dharma in Silver Lining

- 4” deep stainless steel restaurant tray

- Citric Acid

- Soda Ash

- Gram Scale

- Digital pH tester

- Synthrapol textile detergent

Tencel is a type of rayon, like viscose and modal. These cellulose fibers are all made in a similar way: by dissolving wood pulp and using a special drying process called spinning. Before drying, the wood chips are mixed with a solvent to produce a wet mixture. This mixture is then pushed through small holes to form threads, chemically treated, then the lengths of fiber are spun into yarn. (source: https://goodonyou.eco/how-ethical-is-tencel/)

Dye Science Lesson:

Asperitas is 50% tencel and 50% recycled wool. Protein fibers (anything from an animal, like silk, wool, alpaca etc.) require an acidic bath and acid reactive dyes to absorb and retain the pigment molecules. Cellulose fibers (anything derived from a plant like bamboo, tencel, cotton etc.) require an alkaline bath and fiber reactive dyes to absorb and retain the pigment molecules.

What is pH?

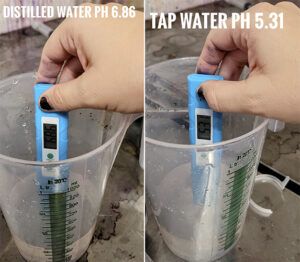

pH is a scale representing the acidity or alkalinity of a solution. The values range from 0 to 14. 7 means neutral, below 7 means more acidic, and above 7 means more alkaline.

Every chemical reaction works best at a certain pH, or degree of acidity.

Here’s the pH reading of my regular tap water vs distilled water for a baseline comparison. I decided not to use distilled water because my tap was already somewhat acidic.

Acid dyes

In the case of acid dyeing, a low pH helps to form the hydrogen bonds that attach acid dyes to protein fibers. Acid dyes do not work on cellulose fibers. Optimal pH varies according to the specific type of acid dye. Today we are using a leveling dye from Aljo and the pH range is 2.5 – 3.5 (source: www.pburch.net)

I added 2 teaspoons of citric acid to 2 gallons of hot water in a 4” deep stainless steel restaurant tray. The pH tester is from Amazon and cost $10, I highly recommend you get a digital tester instead of the paper dip strips. Less mess, less confusion, nothing to throw in the trash or repurchase, more accurate results.

For this pattern, the goal is an even, solid-shade yarn. I know that only 50% of the fiber content will grab the acid dye on the wool portion, so I’m going to go with 1% d.o.s. (degree of strength per weight of goods) and the formula looks like this:

300 grams yarn x 1% d.o.s. = 3 grams of dye

I dissolved the dye in 2 gallons of very hot water and let cool to room temperature. I submerged the skeins in the dye bath without acid and let them sit for 12 hours. If I put them in a hot acidic bath, the “hot spots” will attract dye more quickly and I’ll have dark and light patches that distract from the pattern.

I slowly bring the wool up to 210 degrees Fahrenheit on induction and add in the acid slurry while carefully turning the fiber so the dye strikes slowly and evenly. Let cool to room temperature before rinsing. Here’s the results: Crystal clear dye bath and a nice solid shade. Remember to adjust your dye value (how much dye in proportion to the weight of the yarn) to half your usual strength since only half the content can absorb the dye. Otherwise, something like 4% d.o.s. Black will actually be 8% and you’ll have a bleeding mess on your hands.

Now onto the tencel dye! I chose the fiber-reactive dye Silver Lining from Dharma Trading and our mordant (an inorganic oxide that combines with a dye or stain and thereby fixes it in a material) is soda ash. Soda ash is the active ingredient in washing soda. The chemical name for it is sodium carbonate. It’s more basic, meaning less acidic, than sodium bicarbonate (baking soda). Soda ash will increase the pH of your water to the level that allows the fiber-reactive dye to strike, between 9-11.

Dissolve a quarter cup of soda ash in 2 gallons of hot water in a 4” stainless steel tray and soak your yarn for half an hour. Dissolve the Silver Lining dye in 1000ml of hot water, remove the yarn from the tray, add the dye to the soda ash bath and return yarn gently distributing to ensure even dye penetration. Unlike acid dyes on protein fibers, there is no heating required with cellulose fibers. The drawback is that you need to let the dye cure for 24 hours, and there will be a significant amount of “bleed” (unbound dye) that can be frustrating to rinse out. I chose 1.5% d.o.s. to account for the amount of dye that will wash out (essentially 3% per the weight of the tencel content, knowing I’ll lose about 50% of the dye saturation to rinse out).

After 24 hours, I transfer the yarn to a clear bucket and do a series of 60 second sprayer rinses followed by a bath in the clear bucket to see if there’s any loose dye bleeding out. For this blend and this saturation, it only took one wash and one rinse cycle to be clear.

Here’s our results! A beautiful, pearlescent, perfectly even gray and the hand of the yarn was not negatively affected by the soda ash.

Here are the two swatches side by side in the sun. Even though we used a third less dye for the wool portion, it is still significantly darker. This is due to the fact that, under the right conditions, 100% of the dye can be absorbed with acid reactive dyes on protein fibers, whereas cellulose fibers do not grab nearly as much dye and quite a bit is lost at rinse out. I have not found a sufficient answer as to the chemistry behind why protein fibers dye so much easier than cellulose fibers. But we all know the experience of buying a red t-shirt that accidentally stains an entire load of white laundry pink. Forever. So if the big textile mills can’t get a stable cotton dye, how can us hand dyers expect to get something better?

Hope you enjoyed learning about the chemistry behind the 2 blends featured in the Asperitas yarn and this informs how you approach your next dye batch.

Until next time,

Nic Frost