Dying new summer blend yarn Verano with fiber reactive dyes

Featuring: Verano from Knomad

60% Fine Superwash Merino Wool 21.5 mic

30% Pima Cotton

10% Linen

Our Goal: Do a mini study on a mixed fiber base to see the difference in dye uptake and speckleability

Abstract: Fiber reactive dyes for cotton also work on wool – we just need a different Ph in the dye bath to dye for the cotton/linen content vs the wool content.

-Does it speckle differently when dyed for wool vs cotton?

-What does the same amount of dye look like speckled vs a semi solid tonal?

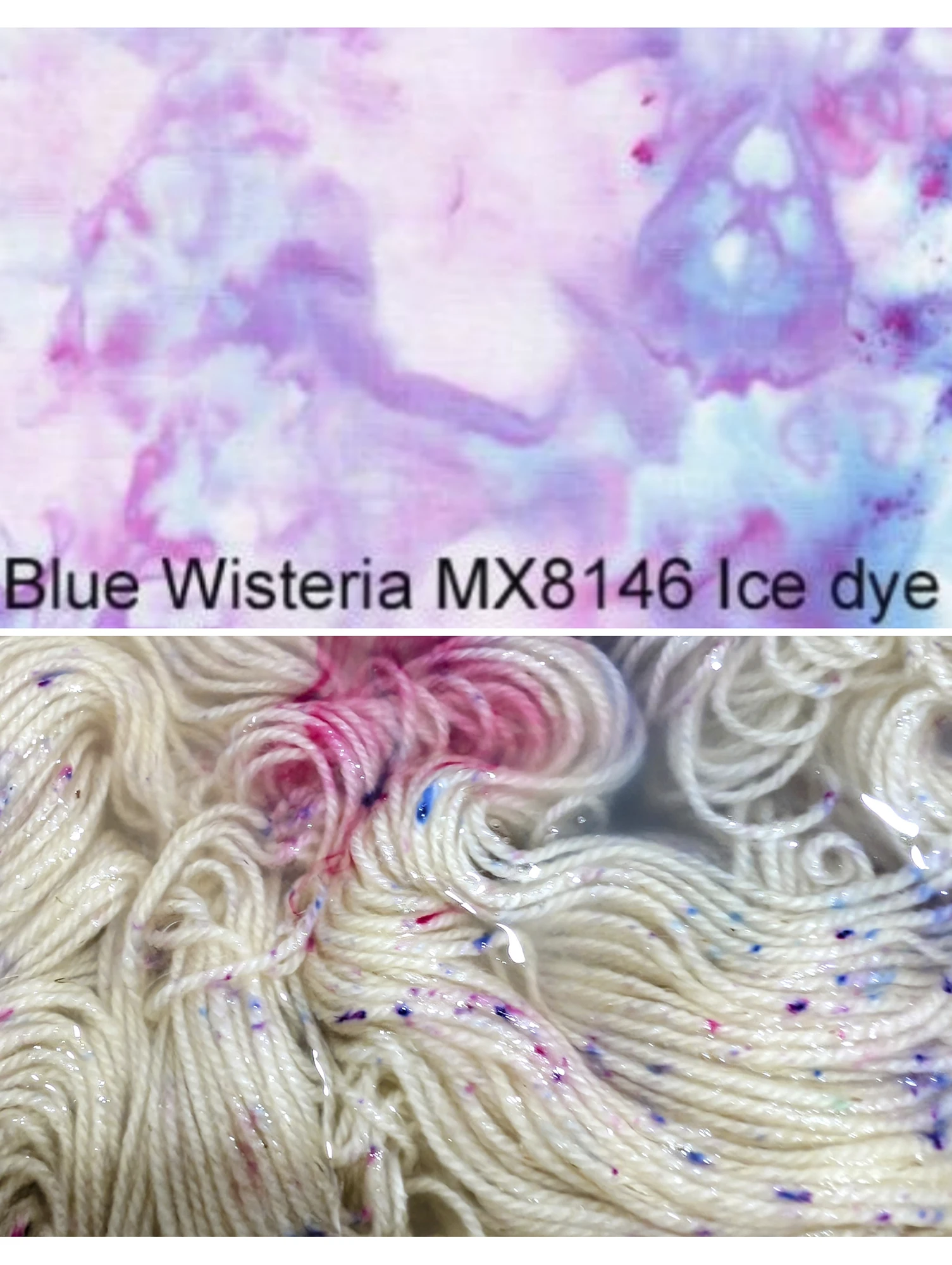

-Do dyes that split on fabric when ice dyed translate well onto yarn?

For those with time to read the finer details, let’s dive in!

YOU WILL NEED:

-5 skeins of Verano

-Heat protectant gloves

-Shower Rings

-Respirator

-Double Burner Induction Cooktop

-Fiber Reactive Dye from Pro Chem in Blue Wisteria

-4” deep stainless steel restaurant tray

-Citric Acid

-Soda Ash

-Gram Scale

Attach plastic shower rings to the yarn, I used black ones on the skeins dyed for the cotton content and white ones for the skeins dyed for the wool content to be able to tell them apart.

Fill a 4” deep tray with 4000 ML of warm water and 1 tsp of Synthrapol. Lay in all 5 skeins and let them soak for a few hours at a minimum to overnight for best water penetration. If patches are dry, they’ll resist the dye and cotton takes a while to thoroughly wet.

Next, prepare 3 dye baths:

Cotton Speckle Experiment:

-One Tablespoon of soda ash to 2000 ml of warm water in a stainless steel tray with 2 skeins laid side by side.

Wool Speckle Experiment:

-One Tablespoon of citric acid to 2000 ml of warm water in a stainless steel tray with 2 skeins laid side by side.

Wool Semi Solid Tonal Experiment:

-One Teaspoon of citric acid to 3000 ml of warm water in a tray or pot with 1 gram of Blue Wisteria dissolved into the dye bath

The goal is a 1% depth of shade for all skeins so we can see the difference in how Verano speckles when prepared for the cotton/linen content vs the wool content, and how the color looks as a semi solid tonal dyed for the wool content.

Measure out 2 grams of Blue Wisteria

Take your tray of citric acid soaked skeins and put them on the induction burner, bringing them up to about 210 degrees, just under boiling.

Lightly speckle the dry dye powder over the length of both skeins, moving back and forth top to bottom dropping tiny amounts as you go.

Leave on the burner, but not boiling, for 22 minutes. Let the skeins cool to room temperature before rinsing and laying out to dry.

Next up, our cellulose dyed pair! Repeat the speckling process on the induction burner at 160 degrees instead of 210.

Typically, the process for setting cotton takes significantly longer than wool, ranging anywhere from 12-24 hours. However, in my ice dye experiments, I found out that you can speed up the bonding process with heat! I set my induction to 160 degrees for one hour, then let it sit for a second hour before rinsing.

Our third experiment will be a solid shade at 1% degree of strength. That means 1 gram of dye per 100g of yarn. I was just curious to see what a color like Wisteria would look like unbroken, and how much color saturation we get from a dye meant for a pastel effect. A teaspoon of citric acid and 2000 ml of water on the burner for 22 minutes. Let cool to room temperature before rinsing and hanging to dry.

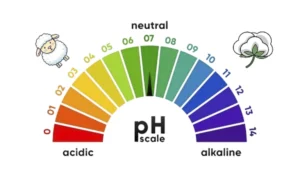

Before we jump into the results, let’s talk a little bit about the difference between acid reactive dyes and fiber reactive dyes.

Acid reactive dyes are formulated for protein fibers like wool, silk and anything that comes from an animal. They require an acid to bond to the fiber like citric acid or vinegar. They require a Ph of 3-4 for optimal results

Fiber reactive dyes are formulated for cellulose fibers like cotton and bamboo, anything that grows out of the ground. They require a Ph of approximately 10.5 for optimal results.

Fiber Reactive dyes work on protein and cellulose fibers.

For reasons I cannot fathom nor find the answer to online, Acid Reactive dyes do not work on cellulose fibers at all. The best you’re gonna do is stain the cotton and it will fade very quickly.

This means that purchasing fiber reactive dye is a better investment for the home dyer who wants one dye to work on the full spectrum of natural fibers they might acquire.

The only downfall I’ve found to using fiber reactive dyes vs acid reactive is a more limited color range of primaries. There is no true scorching neon hot pink, nor any true neons for that matter.

My swatch of Pro Chem’s acid reactive hot pink on top, and Pro Chem’s fiber reactive swatch of hot pink on bottom. Not a true neon and far more “fuschia red” than pink in real life.

The difference is very subtle between how each skein took the speckles. I’d say on the cotton side, the speckles are paler and somewhat less vibrant despite using identical amounts.

These colors are formulated to “split” when used on cotton fabric where the dye is sprinkled over ice. I like to think of the “ice dye splitting colors” as excellent speckling colors for yarn because they create a multitude of different speckle colors within a single color.

Our semi solid tonal skein came out beautifully as well, it has that delicate watercolor effect and would coordinate nicely with the speckled skeins in a project. Since the wool content is superwash, the dye grabbed fairly quickly which gives us the characteristic marbled effect of hand dyed yarn. If you wanted more of a solid shade, I’d recommend dyeing for the cotton content and letting it sit in the bath overnight without heat.

Hope you enjoyed this months installment of fiber fun on a wonderful new base that’s perfect for summer! Til next time, Nic.