How undyed yarn is made: Quality Control

Now on our video series, we get a behind the scenes look at our quality control department, and meet some of the folks who ensure a quality product for all our hand dye fibre artists!

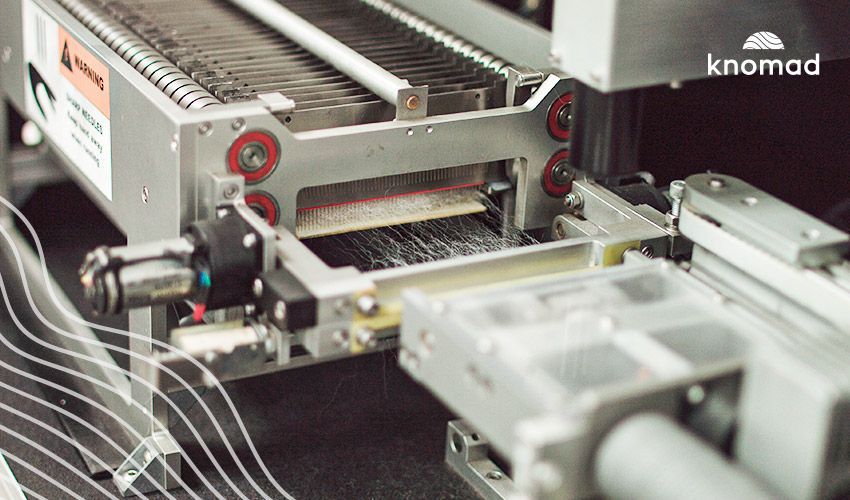

The quality control department uses sophisticated instruments to detect inconsistencies in the fibre at a micro level. They thoroughly review the fibre that goes into all Knomad yarns for length, softness and purity. Only the best fibres earn the prize of becoming part of Knomad’s exquisite line of yarn. From the field, to the mill, and on to the warehouse, we are fortunate to work with the best in the business when it comes to fibres. But enough from me, let’s hear directly from our fibre expert, Carlos Rodriguez, about the important work of our quality control department!

Tags: Beginners, Hand dyers, indie dyers